We visited STV Technology s.r.o., which focuses on the production of small calibre ammunition

In the premises of Poličské strojírny, historically the first ammunition factory founded in 1920, we find the company STV Technology, s.r.o. This company, which was established only in 2017, focuses on the production of small-calibre ammunition. These are 9 mm Luger pistol cartridges. The company also deals with the conversion of originally military cartridges for civilian use. Thanks to massive investments, it plans to expand its production by offering .223 Rem. cartridges for the civilian market and military ammunition in 9x19 mm (9 mm NATO) and 5.56x45 mm (5.56 mm NATO) calibers. STV Technology's exports are directed to the whole world except the Far East. Their products can therefore be found throughout the European Union, the United States, Latin America, Africa, the Middle East and of course here.

Video: Report from the visit of STV Technology s.r.o., which focuses on the production of small calibre ammunition / YouTube

The dynamic development of the company was also confirmed by its managing director and our guide Pavel Kudrhalt: "We are completing an investment well in excess of half a billion crowns, expanding the production capacity for 9 mm Luger cartridges and introducing new technologies for the production of .223 Rem. At the end of July we will take delivery of the first machinery for .223 Remington. The second phase of deliveries of this equipment will take place during September. The acquired machines will produce up to 160 million rounds per year. Roughly the same volume will be produced for the .223 Remington cartridge. The goal is to have our 9x19 mm (NATO) and 5.56x45 mm (NATO) cartridges classified to STANAG standards during the first quarter of 2023. This includes production versions of the 9x19 mm, 5.56x45 M193 and 5.56x45 SS109.

In order to offer its customers a more comprehensive range of ammunition, STV Technology's next investment is in machinery for the production of the widely used 7.62x39mm cartridge and the increasingly popular .300AAC Blackout. This is the company's response to current market developments that offer the possibility of exporting these cartridges, particularly to the USA, where there is currently a shortage of some 800 million rounds of 7.62x39 ammunition. "We see this as a huge business opportunity. We expect to start production of these calibers in 2024. We already have the production facilities ready for this, which otherwise usually hinders rapid development," added Pavel Kudrhalt. The key investment for the future remains the expansion of production by two more production facilities for the 9 mm Luger type and two more - for the .223 Rem. cartridge in combination with the 5.56x45 mm cartridge. The full start of production after these investments will take place during the first half of 2026. The projected capacity of all - already operating and new facilities - is about 850 million rounds per year. The total investment in this phase will amount to almost CZK 1 billion.

Picture: View of one of the production halls | Michal Pivoňka / CZ DEFENCE

Picture: View of one of the production halls | Michal Pivoňka / CZ DEFENCE

This capacity will also place considerable demands on the strengthening of logistics. "We are also counting on strengthening the software to ensure maximum automation of operations and online data collection. We place the utmost emphasis on product quality. An important part of production is therefore the set-up of individual production processes and, above all, strict adherence to technological procedures and subsequent quality control at all stages of production. As a relatively new company, we cannot afford not to have first-class hubs," added Pavel Kudrhalt.

As mentioned above, quality control of ammunition is a priority at STV Technology. It takes place on several levels. At the beginning, the material undergoes an initial inspection. All deliveries must have the required certificates and evidence of the supplier's exit inspection. The plant processes large quantities of brass and lead in various modifications. "Therefore, during the incoming inspection of brass materials, we focus on the composition of the material, use precision spectrometers, check hardness and grain size. As part of the new investment, we will be acquiring equipment to test the energetic components of the ammunition. We will be testing primer sensitivity, primer initiation and firing power. For smokeless powders, we will test grain size, chemical composition, graphite content and burn rate," the managing director explained.

Picture: Press for cutting out the lead core of a bullet | Michal Pivoňka / CZ DEFENCE

Picture: Press for cutting out the lead core of a bullet | Michal Pivoňka / CZ DEFENCE

The next level of quality monitoring is production control, which has three stages. It all starts with the operators. They measure 10 pieces of mouldings every ten minutes. If any non-conformity is detected, they stop the machine and call in the adjusters. All the parts produced in the last 10 minutes of production are withdrawn to the so-called "quarantine" and manually checked. The second level of production inter-operation control is a random check at any part of the production process. Its essence is that the controller takes samples from the running production every two hours. If a defect is detected, the machine concerned is stopped, the last two hours of production are separated and the parts are sent back to quarantine. They are returned to production only if a manual inspection report is issued and the parts are satisfactory in all respects. The third level of inter-operational inspection is a 100% inspection of the parts (cartridge and projectile) using extremely accurate optical inspection systems.

Picture: Press for drawing the bullet cup and bullet assembly | Michal Pivoňka / CZ DEFENCE

The last level of inspection is the output inspection of the finished hub. It is a 100% optical inspection of the dimensions of the bullet, visual inspection of its packaging and last but not least a regular ballistic inspection. "The magic of our final hub quality lies in precision components, regular and careful maintenance of the machines, good tools, trained and experienced operators, adherence to technological procedures and quality input materials. Currently, the proportion of non-conforming products is less than half a percent, both in components and in the finished hub," summarised Pavel Kudrhalt.

This control system enables the traceability of a possible error by batch to the level of material input into production. In the case of a defect in a cartridge case, the batch number can be used to find out who the cups came from, when they arrived and what their serial number is. "We check one hundred per cent of production with optical machines. Especially dimensions, surface defects and shape defects. It was my personal request, which may have made production more expensive, but as a new company on the market we cannot afford quality problems," explained Pavel Kudrhalt and added: "From May last year until today we have had one complaint, and that was about a malfunction of the primer of the cartridge, which is a purchased component, but it was our cartridge, so we accepted the complaint."

Picture: Press for inserting the primer into the rim | Michal Pivoňka / CZ DEFENCE

Picture: Press for inserting the primer into the rim | Michal Pivoňka / CZ DEFENCE

The key to a well-functioning cartridge is quality powder and primer. The suppliers for STV Technology are from France, Belgium and the USA. STV Technology sources its primers from the world's leading manufacturers.

Just as it is important to carry out inspections, it is essential to have a sophisticated maintenance system so that the machines do not stand idle unnecessarily in continuous operation. Again, there are several levels involved. The most basic is regular maintenance of the machine during the shift. This involves cleaning, vacuuming and, if necessary, changing tools. The next step is post-shift maintenance when the machine is handed over between shifts. Next is weekly service - there is a two-hour maintenance on Friday after the afternoon shift, followed by monthly, quarterly, semi-annual and annual maintenance. At the semi-annual maintenance, technicians come directly from the machine manufacturers to perform a detailed inspection and recommend replacements or repairs. The annual overhaul is then carried out during the company-wide holiday period. The machine is dismantled and all parts are inspected: cams, motors and shafts. All key machine components also have an extended warranty period.

Picture: Combined machine for cartridge assembly | Michal Pivoňka / CZ DEFENCE

Picture: Combined machine for cartridge assembly | Michal Pivoňka / CZ DEFENCE

As part of our visit, we were given the opportunity to check the characteristics of the manufactured 9 mm Luger pistol cartridge ourselves on the company's shooting range and we have to admit that it is user-friendly and forgiving of shooting errors. The cartridge is suitable for the shooting public who do not require extreme performance, yet the cartridge provides unparalleled accuracy and reliability.

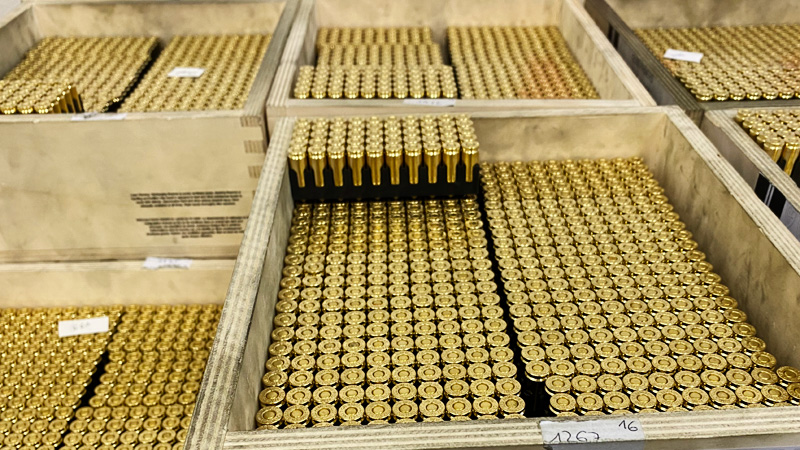

Picture: STV Technology s.r.o. focuses on the production of small calibre ammunition | Michal Pivoňka / CZ DEFENCE

Picture: STV Technology s.r.o. focuses on the production of small calibre ammunition | Michal Pivoňka / CZ DEFENCE

Beyond the investments already mentioned, STV Technology is also building its own capacity to manufacture pistol and rifle primers and produce .50 BMG (12.7x99) caliber ammunition. The anticipated commissioning date is the end of 2024, but more on that next time.